- Home |

- Electrical Panel Cleaning Solution

Electrical Panel Cleaning Solution

Sun Petrochemicalss, Mumbai is pioneer in online electrical panel cleaning in India

FREQUENTLY ASKED QUESTIONS (FAQs)

- It is called Electrical and Electronic Component Dust Cleaner and is available in liquid form

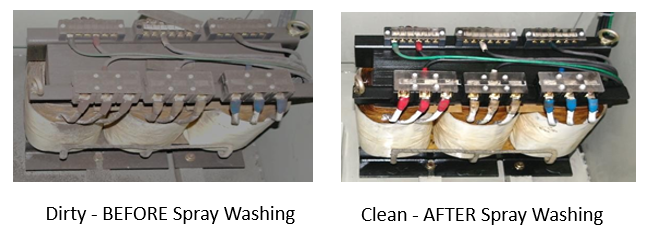

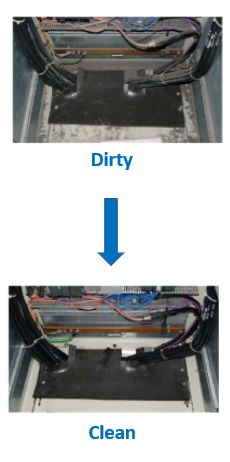

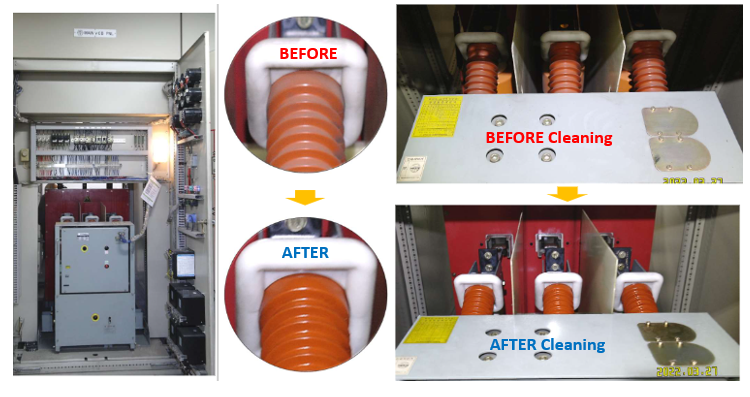

- Electrical and Electronic Component Dust Cleaning Liquid mixed with compressed Air, is sprayed on the components to be cleaned to remove the contaminants. The Direction of the spray is maintained from TOP SIDE to BOTTOM SIDE

- The Electrical and Electronic Component Dust Cleaning liquid flushes out the dust and flows down towards the bottom of the Electrical Panel or Equipment.

- The Spray guns are provided with NON-CONDUCTIVE material coating to with-stand High Voltage equipment up to 50000 Volts

- The process is manual and it is used to clean all electrical and electronic – components, panels or equipment in BOTH POWER ON or POWER OFF mode

- The Dust Cleaning liquid is 100% NON-CONDUCTIVE and the same is designed with special detergents which can easily remove – DUST, THIN OIL TRACES and MOISTURE from electrical and electronic components and equipment

- Once the dust cleaning liquid is sprayed on the surface components to be cleaned – with its special properties, the cleaning liquid quickly detaches the dust and oil traces from the affected surface and flushes the same towards the bottom of the panel.

- Moisture, if any, in the inner side of the components / panel / equipment is made to evaporate along with dust cleaning liquid (It’s the chemical configuration of Cleaning liquid which helps the moisture to evaporate)

- The dust cleaning liquid also has special property with which it creates an anti-corrosive micro layer on the panel / equipment surface instantly STOPING further corrosion

- NO… there is absolutely NO NEGATIVE effect of the Dust Cleaning Liquid on component surface

- NO STAINS/DEPOSITIONS/RESIDUE is formed on the surface of the components on which dust cleaning liquid is sprayed

- The Dust Cleaning Liquid is NON-ACIDIC

- The Dust Cleaning Liquid is NON-EROSIVE

- Dust Free Electrical & Electronic components with NO sparking and Arcing

- Reduction in heat losses due to dust removal

- Reduction in component temperature due to reduced heat losses

- NO Shut Down required during dust cleaning activity (No-Break equipment)

- Minimized Component Failures

- Reduction in Annual Maintenance / repairing Costs

- Extended Life of Equipment

- Safety against Fire and Accidents

- Effect of cleaning remains for 6# months to 12# months depending on the surrounding environment, dust levels and overall weather

TYPE 1 = SP Insta Clean 100

- 100% Electrically Non-Conductive

- Best Suitable for all Electrical and Electronic components

- Lesser consumption and higher cleaning area due to slow evaporation characteristic

- Preferred for cleaning of all electrical panels up to 50 kV voltage capacity and Control panels

TYPE 2= SP Insta Clean 200

- 100% Electrically Non-Conductive

- Best Suitable for all UPS, Data Center Equipment, Electrical equipment in Mines, Tunnels and submarines

- Most preferred for highly critical applications, poorly ventilated and Under-ground Installations 30 kV Voltage

- SAFE to use product. It can be used as a Fire Extinguisher in case of Fire

- There is ABSOLUTELY NO CHANGE in Chemical properties of dust cleaning liquid with aging

- The only thing is that the dust cleaning liquid evaporates quickly and if the container is kept open the liquid will get exhausted very fast

- ABSOLUTELY NO. You are NOT SUPPOSED to DILUTE / MODIFY / MIX water or any other liquid / substance in to SP Insta Clean 100 / SP Insta Clean 200. It must be used AS IT IS.

- There is NO SPECIFIC FORMULAE to calculate the consumption of dust cleaning liquid for obvious reasons and the consumption purely depends on;

– Dust / dirt deposition volume on the electrical and electronic components. If it is more dusty or dirty; then the consumption of dust cleaning liquid will be more

– Stickiness of dust or dirt. If it is stickier; then the consumption of the dust cleaning liquid will be more

– Age of the electrical and electronic components. If the age is more; the consumption of the dust cleaning liquid will be more

- ABSOLUTELY NO…. The disconnection of power can happen only when the Lugs of Two cables are not tightened or not connected properly.

- ABSOLUTELY NO. The dust cleaning liquid is non-conductive and does not have any property which is harmful for the overall health of the respective panel.

- In past 3 years we have NOT RECEIVED a single complaint

- Yes, the liquid and spraying accessories can be used in Gas and Oil industry.

- Shock proof / Fire Proof / Heat Proof Suit, Insulated Rubber Gloves, GAS Mask, Helmet or Headgear with Flash Light, Eye Protection Glasses, Safety Shoes, Multi-pocket Pants for holding small equipment (All should be of suitable rating from 110 V to 33000 Voltas)

- Not mandatory at all as the dust cleaning liquid evaporates quickly. However, the end users can

make a provision if that is possible – It is there choice

- In case of extreme temperature above 55 Deg. C the room or space in which the dust cleaning liquid is stored should be ventilated considering minimum 10 to 15 Air changes

- The dust cleaning liquid is supplied in to containers (drums) having bung holes which are provided with properly designed plugs and round covers to it. Here the only precaution to be taken is – NOT TO EXPOSE the liquid directly to Moisture, Water, Fire i.e. always keep the bungholes of the drums closed with appropriate plugs and cover.

- The liquid will evaporate quickly if the bunghole is kept open or uncovered.

- There is NO time limit for consumption. The only thing is; we need to take precautions to avoid evaporation of the dust cleaning liquid as detailed above

- Yes, the liquid will evaporate as explained earlier. However, it will not have harmful impact on environment

- NO….. this is purely a cleaning solution meant for maintenance purpose and NO such permission / approval /BIS certification is required for this product

Clean Your Electrical Panels In a POWER ON MODE

Introduction to Cleaning Liquid

- It is a Hybrid Liquid designed with special detergents to clean Electrical and Electronic Components

- The cleaning liquid has NO conductivity and when sprayed on the components detaches; dust, oil, and moisture from sensitive surfaces

- The liquid penetrates to the deepest area & flushes out the dust particles with pinpoint precision

- The cleaning liquid dries up quickly and leaves NO residue or stains on cleaned surface

- It forms an anti corrosive micro layer on the component surface instantly which stops further corrosion

- It is a completely - Safe, ECO-Friendly and Disaster Free product

Salient Features of The Cleaning Liquid

- The Non Conductive cleaning liquid can clean electrical equipment up to 55,000 Volts in a POWER ‘ON’ or ‘LIVE’ Mode

- It Neutralizes the electro static particles or noise generated by air compressor during cleaning

- Reduces the temperature of the Electrical Panel by 20% to 30% or more depending on the AGE of the Panel

Benefits For End User

- Prevention of malfunctioning of electric and electronic components reducing downtime

- Safety against accidents, fire

- Extended life of electrical and electronic components

Applications

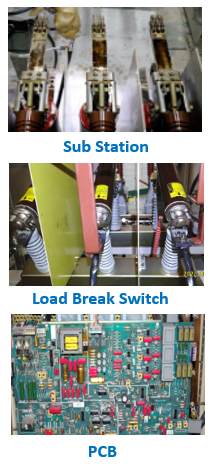

- Electrical Panels;

- HT / LT Panels and All sub panels

- Escalator, Elevator, Conveyor belt Panels

- Crane and Earth Moving Equipment Panels

- CNC Machine Panels

- Railway Train Electrical Panels

- Electrical Motors (Servicing and Maintenance)

- Variable Frequency Drives

- IDC (Insulation Displacement Contact) Center - UPS Server

- PLCs with HMIs

- Generator alternator

- Electronic Equipment

Main VCB

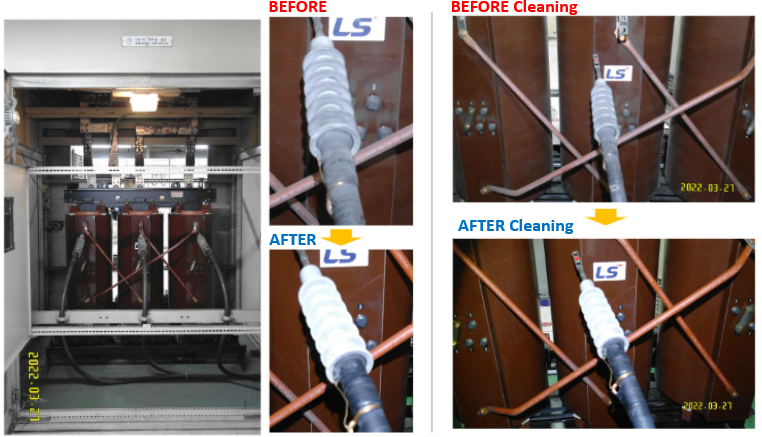

Transformer 1000 KVA

HT Control Panel, water pipes Rectifiers

Electrical Motor (Servicing)