- Home |

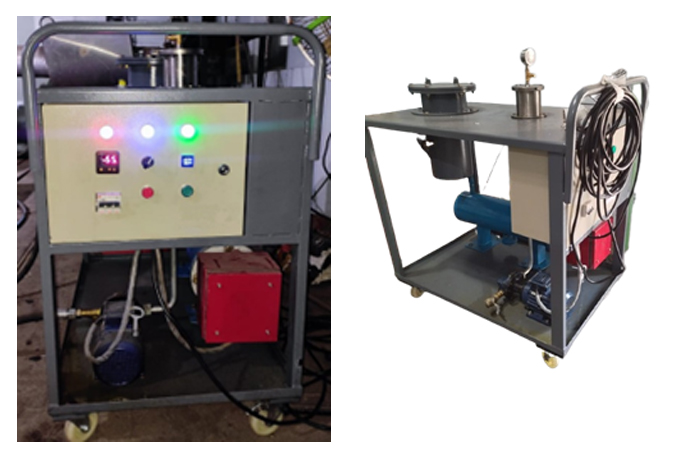

- Oil Water Separation (Dehydration) Systems

Oil Water Separation (Dehydration) Systems

Why Oil Water Separation (Dehydration) Systems is required?

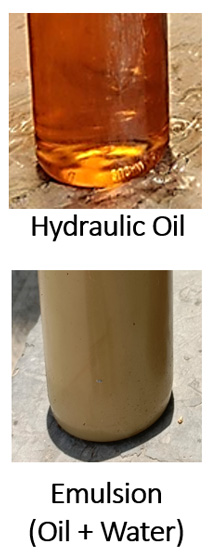

- In any machine it is very important to avoid mixing of Oil (Hydraulic, Lubrication, Others) and water or coolant as the viscosity of the same is affected causing serious issues like machine breakdowns

- Normally; water or coolant leaks through gaskets, seals, damaged hydraulic pipes and gets mixed with oil diluting it

- Water in free or dissolved form causes severe lubricant degradation RESULTING IN:

- Oxidation and corrosion within all the moving parts, bearings and gearboxes

- Wastage of Oil and increased cost

- Sludge generation and frequent break downs

- Overheating, Seizing, Blockage, Cavitation

Conclusion: Removal of Water from Oil is a must !

Oil Water Separation (Dehydration) Systems Performance

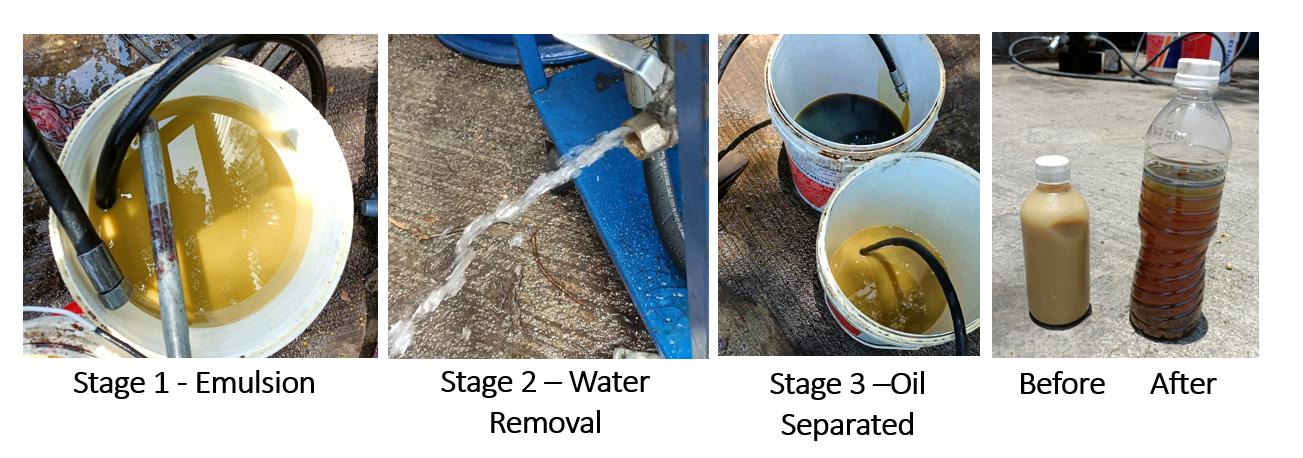

- The emulsion (Oil-Water mixture) from the machine tank is circulated through our Oil – Water Dehydration System in an off-line mode without disturbing the Oil or Coolant flow

- The filter element removes contamination effectively and then passes the mixture to the second chamber

- The emulsion is then heated in the second chamber under designed pressure conditions causing the water vapor to settle at the bottom which can be drained out. Oil free of water ensures overall REDUCTIONS IN –

- Corrosion of the internal components of the oil lubricated rotating equipment.

- Waste oil & disposal cost- savings in recurring new oil purchase

- Machine failures, maintenance cost

Benefits:

- Recovers Oil from Emulsion easily

- Saves Oil cost

- Cleaning and Heating operations are automatic

- Saves Environment

Capacity & Efficiency:

- Capacity : 5 lpm & 10 lpm

- Removes water and any kind of solid particles available in Emulsion

- Same machine can adapt cellulose based filtering elements

Types of Emulsions & Machines:

- All Types of combinations of Oil + Water

- Stamping Machines

- Press Machines

- Equivalent applications

Special Features:

- With Trolley and MSPC Casing, Compact, Noise less

- Filter element replacement takes only 5 minutes by unskilled worker

- Almost 0 maintenance & 20 Yrs life