- Home |

- Oil Filtration & Coolant Cleaning Systems

Oil Filtration & Coolant Cleaning Systems

Why Oil Cleaning & Filtration System is required?

- 80% of the Oil Lubricated System failures are due to high contamination levels in the oil

- Any particulates inside oil lubrication system generate new particles which act as catalyst causing oxidation, additive depletion & formation of sludge

- Water in moisture form causes severe lubricant degradation, oxidation & corrosion within equipment.

- All these cumulative effects RESULT IN:

- Contamination - Dust generation, aberration and chemical formation

- Increased; Viscosity, TAN No., Surface Tension & Sludge generation

- Malfunction Through – Corrosion, Overheating, Seizing, Blockage, Cavitation

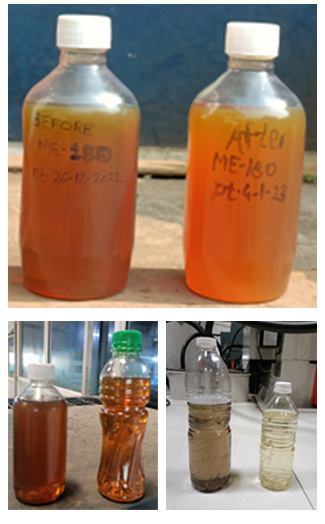

Conclusion: Removal of Contamination and Moisture from Oil is a must !

Oil Cleaning & Filtration System Performance

- The Oil (Hydraulic/Lube/Equivalent) from the machine sump is circulated through our Oil Cleaning System in an off-line mode without disturbing the Oil flow to the machine components

- Specially designed filter element removes solid particles up to 3 / 5 microns effectively along with moisture content

- Clean Oil ensures increased productivity and RESULTS IN –

- Reduced - Wear & tear of moving parts and Bearings, its replacement frequency & conditioning costs

- Reduced - Machine Break downs, Maintenance time, Production losses

- Enhanced - Oil Life; saving Oil costs significantly

- Improved - NAS value and System efficiency

TECHNICAL FEATURES:

- Suitable for all mineral and Synthetic Lube oils

- Model range - 3 lpm to 100 LPM - based on oil volume & viscosity

- Working pressure: up to 6 Kg/cm² (g)

- Design pressure: up to 10 Kg/cm² ( g)

- Working Temperature: up to 90° C

FILTRATION ABILITY:

- 3 μm absolute: for hydraulic and Turbine Oils 98% of all solid particles

- 3 μm are retained in each pass

- 5 μm absolute: For the Heavier Gear Oils -98% of all solid particles

- 5 μm are retained in each pass

- Designed to filter oils from ISO VG 46 to 680 cSt

BENEFITS:

- High Dirt Holding Capacity: Up to 1.5 kgs of Micronic particles and 50% of that moisture holding capacity

- Easy to Operate

- Low Maintenance

- Housings are permanently piped

- Top caps are opened without any special tools and without disturbing the piping

- Portable with Trolley, Noiseless

MOISTURE REMOVAL:

- The water absorption potential of the filter element is up to 2000 ppm.

- Operation: Contaminated fluid enters the housing and is distributed evenly around the filter cartridges. Filtration takes place from outside to inside. Solids are collected on the outside of filter cartridges & clear filtrate is collected at outlet.